+86 400-018-0098

The full-process treatment unit is a comprehensive water treatment equipment with anti-scaling, corrosion inhibition, sterilization, algae-killing, and ultra-purification filtering functions. It addresses the four major issues commonly found in various industrial and civil circulating water systems: corrosion, scaling, bacterial/algal growth, and water quality deterioration. This unit employs multiple patented inventions and proprietary technologies.

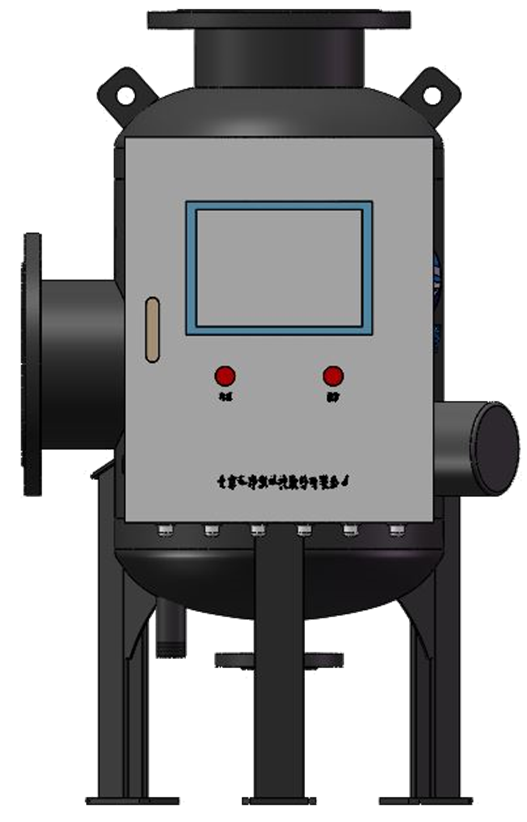

The equipment consists of three main parts: an RF physical field system, a filtering system, and an automatic monitoring system. In terms of principles, structure, configuration, and compliance with national standards, it differs from general and similar types of equipment, with each part having unique advantages.

I. Features of the Radio-frequency Physical Field System

The energy converter uses high-frequency ceramic materials that are resistant to high temperatures, high pressure, impacts, wear, aging, and have an electromagnetic wave conversion resistance close to zero, overcoming significant technical difficulties in the field of circulating water treatment.

The energy converter employs an inductive load, offering large impedance and high electromagnetic wave energy, with transmission frequencies reaching over 10MHz and voltages exceeding 1000V, thereby multiplying the treatment effectiveness. This innovation overcomes major technological bottlenecks in the physical treatment of circulating water.

General energy converters on the market mostly use various metal emission poles and plastic insulation jackets, with emission frequencies around 1 to 3.5 MHZ and voltages from 150 to 500V.

Adopting cutting-edge technology from the aviation sector — the differential rotation shielding effect and multi-point array combination — successfully resolves the significant technical challenges of mutual interference and constraints between radio frequency spectra.

For different water qualities, it uses RF generators with different performance parameters, addressing issues like poor treatment effects caused by the use of the same RF generator for varying water qualities in different regions. This method surpasses the current major technical challenges in the field of circulating water treatment.

II. Features of the Filtration System

The filtration system achieves the goal of continuous operation of filtration, sewage discharge, and filtration in the equipment, effectively removing impurities.

It employs proprietary dual sewage discharge technology — water-quality-based and impurity-based discharge — resolving significant technical challenges in the circulating water treatment field.

Using water quality monitoring parameters, the system automatically adjusts and controls water quality. It can also employ pressure differential for impurity-type sewage discharge. This process addresses a series of major issues caused by the traditional single sewage discharge method, such as large instantaneous sewage discharge volumes, large immediate water replenishment requirements, and easy system pressure fluctuations. It features small instantaneous sewage discharge and stable system pressure.

III. Features of the Automatic Monitoring System

The system uses a self-developed single-board machine-specific automatic control system with a 7-inch touchscreen display, offering faster computational speed, simple operation, an intuitive human-machine interface, and stable operation.

It has capabilities for automatic detection, logging, and display of actual equipment run times, water quality parameters, and automatic data report generation.

It features acoustic-optic alarms and data transmission functions, with a reserved RS485 (MODBUS communication protocol) interface, achieving communication with building automation and other third-party systems. It can also be integrated with a multifunctional water quality online machine for joint control, enabling the whole set of equipment to operate automatically and continuously online. Future upgrades can also accommodate GPRS wireless communication. The data download function is included for convenient access to equipment operation data, alarm messages, and more.